Description

Specification:

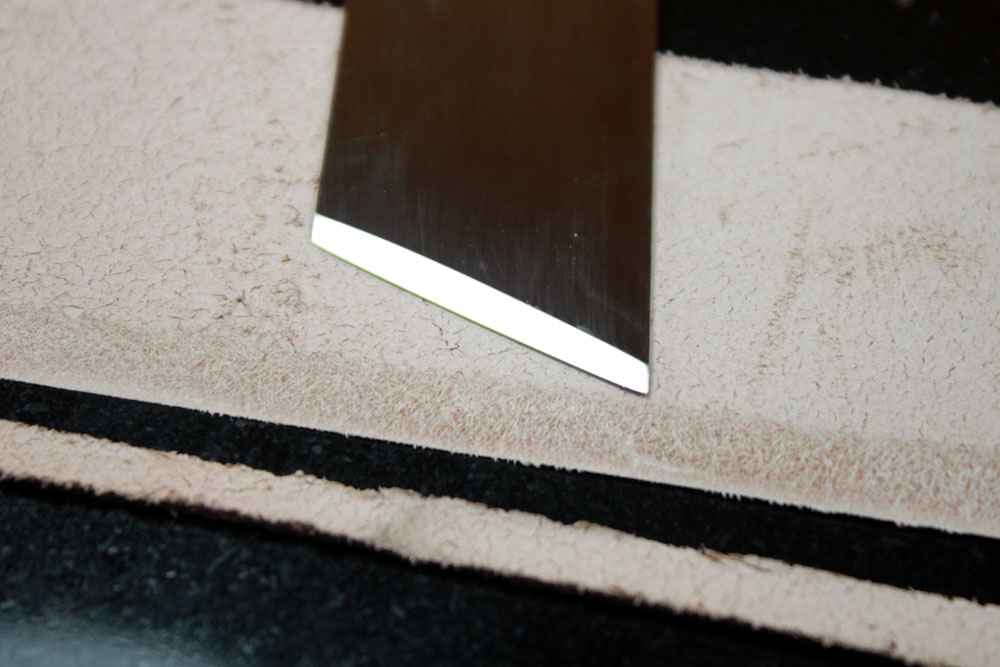

Blade angle: 60°and/or 90º. Left handed version available.

Steel Thickness: 3.4mm at the handle, down to 1mm at the bevel

Handle material: Dessert Ironwood (Olneya Tesot)

Total Weight: 390 grs box included. (Knife 140 grs)

Dimensions: 3cm wide, 19cm long

Steel: Damasteel RWL34, heat-treated by BOS

What is BOS heat treatment?

Heat treating is the process used to impart special qualities to metals and alloys (hardness, strength, ductility, etc.). When heat and subsequent cooling are applied to metals in their solid state, the physical and structural properties (but not the chemical composition) of these metals are changed.

About the materials

Its design guarantees strength, hardness after hardening and purity at all times; It is particularly resistant to corrosion; The cutting edge is maintained over time, and the quality of the cut does not weaken; It is easy to work, grind and polish.

The alloy composition is as follows: Carbon – 1.05%, Manganese – 0.50%, Silicon – 0.50%, Chromium – 14.0%, Molybdenum – 4.00%, Vanadium – 0.20%.

Main benefits include:

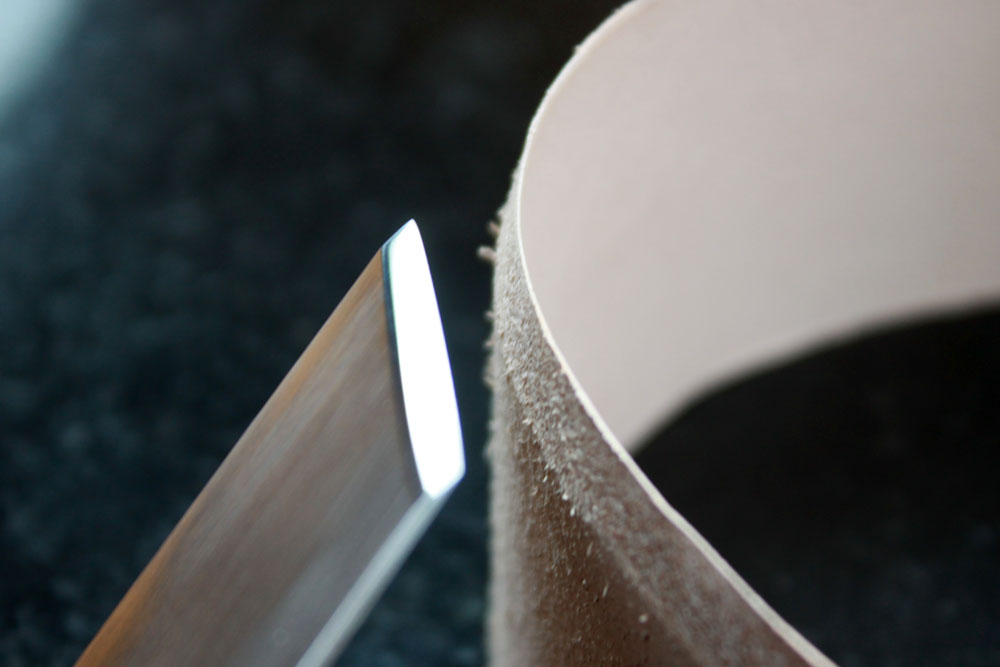

- Edge Retention: RWL34 steel has a high hardness and fine grain structure, which allows it to hold a sharp edge for extended periods of use. This makes it ideal for tasks that require consistent cutting performance.

- Corrosion Resistance: Being a stainless steel, RWL34 is highly resistant to corrosion and rust, making it suitable for use in various environments, especially those with high humidity or exposure to moisture.

- Wear Resistance: RWL34 exhibits excellent wear resistance, ensuring that the blade retains its sharpness even after prolonged use.

- Toughness: Despite its hardness, RWL34 maintains a good level of toughness, reducing the risk of chipping or breaking during demanding tasks.

- Fine Finishing: RWL34 steel is known for its ability to take and hold a fine edge, making it popular among knife makers who seek a high level of craftsmanship and precision in their blades.

Desert Ironwood (Olneya tesota) is a dense and durable hardwood native to the southwestern United States and Mexico. It is highly sought after for its beautiful appearance, strength, and unique characteristics, making it a popular choice for tool handles and other high-end woodworking projects.

Main benefits include:

- Durability: Desert Ironwood is one of the hardest and densest woods available, making it exceptionally durable and resistant to wear and impact. It can withstand heavy use and harsh conditions, making it ideal for tool handles that require strength and longevity.

- Stability: Due to its dense and stable nature, Desert Ironwood is less prone to warping or cracking over time, ensuring that the tool handle remains intact and reliable.

- Natural Beauty: Desert Ironwood is known for its striking color and intricate grain patterns, ranging from dark chocolate brown to deep purple with lighter streaks. This natural beauty adds an aesthetic appeal to the tool and makes it visually appealing.

- Comfortable Grip: The wood’s dense and smooth surface provides a comfortable grip, reducing hand fatigue during extended use and offering a secure hold on the tool.

- Resistance to Moisture: Desert Ironwood has natural oils and resins that contribute to its water-resistant properties, protecting the tool handle from moisture-related issues like swelling or rot.

- Unique Character: Each piece of Desert Ironwood has its own distinct pattern and character, making every tool handle one-of-a-kind and adding a touch of uniqueness to the finished product.

Reviews

There are no reviews yet.